Michro 9100

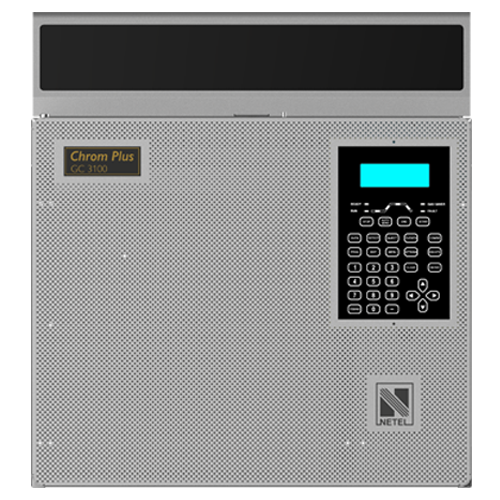

Gas Chromatograph

A rugged, reliable microprocessor based Gas chromatograph forming an essential part of chemical industry with a proven track record of 25 years or more.

- Compatible with specific and non specific detectors having detectivity at par against others.

Industries Covered - Agriculture, Chemical, Environment, Petrochemical, Pharmaceutical, Power Industry, Research

- Modular GC

- Keyboard Control of GC

- Storage of ten methods for GC parameters

- Read-a-flow technique

- Keyboard control carrier gas switch over dedicated capillary injector

- Auto cooling by flap

- Five ramps, six plateaus in single method

- Control of 2 external heated zones and 3 programmable relays

- Dual FID amplifiers

- Remote flame Ignitor

- Dual path TCD

- Auto zero facility

- Audible ready signal

- Protection circuit for column & TCD filament

- Choice of several detectors (FID,TCD,ECD,NPD,FPD etc.)

Optional Attachments:

- Other detectors - ECD, NPD, FPD, PIC, etc.

- Gas sampling (Auto/Manual) 6 port,8ports/ 10 port

- Head Space Sampler

- Column switching' ~ Back flushing arrangement

- Methanizer

- Programable pressure control upto 60 PSI with ramp facilty

Column Oven:

- Dimensions : 25W x 15D x 35H cms

- Volume: 13 Litres

- Temperature stability: ±0.1°C

- Operating Temperature: Ambient to 400°C in

- Range: steps of 0.1°C

- Option: Upgradable to 500°C

- Cooling speed: 250°C to 50°C in 5 mins. (at 20°C ambient temp.) including stabilisation time

- Overheat protection: Protection circuit actives at 20°C over set temp. at the step of 50°C

Temperature Programmer:

- Isothermal Temp. range: Ambient to 400° C in, steps ofO.1°C

- Max. Ramp Rate Programming: Up to 150°C at 30°C/mm. Up to 250°C at 20°C/mm. Up to 325°C at 15°C/mm. Up to 400°C at 10°C/man.

- Number of Ramps: 5 max. (Hold the ramp rate at any time) 999 mm.

- Max. Programme length: 999 mm.

Injection System:

- Single or Dual vertical injectors with Split Split less

- converters for 1/4”, 1/8 or capillary columns

- Operating temp. range: Ambient to 400°C in steps of 0.1°C

- Dedicated port for capillary columns

Pneumatic System:

- Keyboard-operated carrier gas change over system

- Pressure switch cut off mains power in case of

- depletion of carrier gas flow

- Differential flow controllers (DFC) for carrier gas with digital readout

Detector:

Flame Ionisation Detector:

- Design: Forced air diffusion

- Mode: Single or dual column with dual amplifier

- Operating temp. range: Ambient to 400°C

- Sensitivity: >0.017 coulombs/gm.

- Dynamic range: 10â·

- FID amplifier: Max. Sensitivity 5 x 10Amp. Ranges :1,10,100,1000

- Noise: Below 1 x 1013 Amp

Thermal Conductivity Detector:

- Design: Dual path, 4. filaments

- Filaments: Tungsten-Rhenium

- Mode: Dual column

- Operating temp. range: Ambient to 400°C in steps of 0.1°C

- Filament current: 0-400m Arrange

- Temperature stability: ±0.1°C

- Sensitivity: 3500 mI.mv I mg at 80°C temperature (resistance)

- Electronics: Full- Bridge (constant temperature resistance), mode, with filament temp.

- Filament temp.: 150-450°C In steps of 75°C

Specification:

- Size: 76W x 540 x 58 H cms

- Weight: 86 kgs. (approx.)

- Power requirement: 230V or 50 Hz

Agrochemicals:

- Evaluation of technical & formulated material complying BIS & relevant bodies

API/BDI industries :

Estimation of residual solvents using HSS.

- Estimation of residual solvents using HSS.

- Control the quality of solvents/raw materials/reagents.

- To monitor the course of the reaction whenever possible.

Environmental:

- Monitoring the Bap content with other PAHs.

- Residual pesticides from drinking water.

- Monitor the Trihalomethane content of the ambient air.

- PCB content of the oil and water.

- Gaseous analysis of Hydrocarbon and permanent gases in ambient air

Power/Energy Sector

- A customised configuration namely TOGA or DGA using Micro9100 as a GC base is an essential requirment in Power/Energy sector.

Petroleum & Refinery:

- Evaluation of quality of Petroleum based products

Perfume Industry:

- Fragrance composition

Food Industry:

- Composition of edible oils with respect to their MUFA,PUFA & SFA evaluation with focus on trans content

Petrochemicals:

- Evaluation of hydrocarbon blending in wax and other blends

Speciality Chemical Industry:

Research:

- Accomplish the special projects that are applicable.

Polymer:

- Evaluation of quality of raw materials in the form of monomers & detection of these monomers at trace levels in polymers

Packaging:

- Estimation of residual solvents from the packaging materials.

Solvent Industry:

- Evaluation of the quality of recoverd/distilled solvents

Beverages:

- Impurity profiling of alcohol produced